Increase the Revenues of Your Waste Company With the Tips Shared in Our Blog Articles

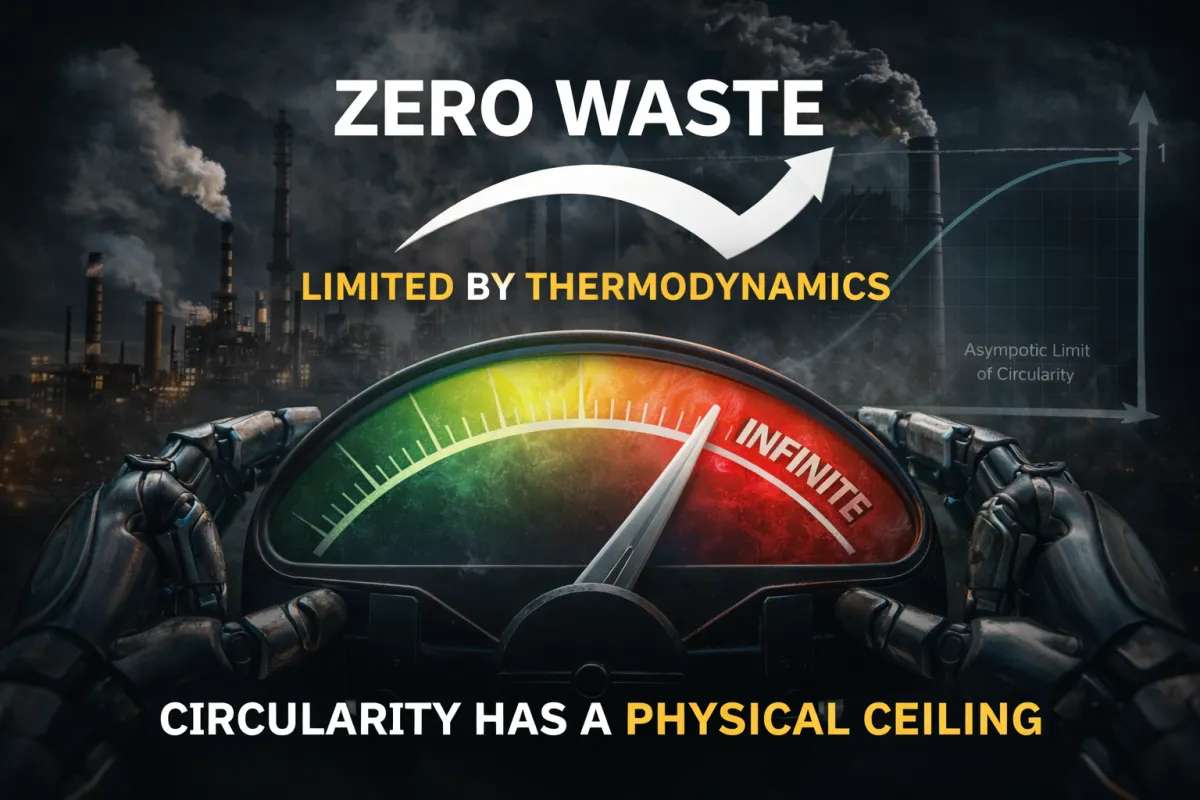

The Dangerous Illusion of Zero Waste

And Why Physics Will Always Have the Final Word

There is a belief spreading across boardrooms, universities, policy circles, and even inside waste companies themselves.

It sounds noble.

It sounds intelligent.

It sounds progressive.

“Zero Waste is achievable.”

Some say:

“With better technology, we’ll reach 100% recycling.”

Others say:

“If we design products properly, waste disappears.”

And the most emotionally powerful claim:

“We must reach Zero Waste to save the planet.”

Let me be very clear.

I am not anti-recovery.

I am not anti-innovation.

I am not anti-environment.

I am pro-physics.

And physics does not negotiate.

In The Asymptotic Limit of Circularity, I explain why absolute circularity collides with thermodynamics.

I want to expand three of the most repeated arguments behind Zero Waste — and dismantle them using chemistry, entropy, and market economics.

Because if you are building a waste business, investing in recovery infrastructure, or positioning your company in the secondary raw materials market…

You cannot afford to build a strategy on slogans.

1. “With Better Technology, We Can Reach 100% Recycling.”

This is the techno-optimist promise.

AI sorting.

Robotic dismantling.

Hydrometallurgical recovery.

Advanced pyrolysis.

Blockchain traceability.

The narrative is seductive:

“Technology will fix it.”

And yes — technology improves recovery rates.

But here is the scientific wall nobody mentions.

As recovery approaches 100%, the energy required does not increase linearly.

It increases asymptotically (in geometry, an asymptote is an imaginary line that a curve approaches as it heads toward infinity).

In thermodynamic terms, separation work is proportional to entropy reduction.

And entropy reduction requires energy input.

When materials are highly concentrated and clean, recovery is efficient.

When materials are dispersed, alloyed, oxidized, contaminated, or chemically bonded into complex matrices…

Separation requires exponentially more energy.

This is not ideology.

This is statistical mechanics.

In my paper, The Asymptotic Limit of Circularity, I explain that complete material circularity would require reversing entropy — an operation that demands infinite energy at the asymptote.

Let’s make it practical.

Recovering large copper cables?

Efficient.

Recovering microscopic copper particles embedded in composite board layers?

Expensive.

Recovering copper ions dissolved in contaminated soil?

Energy-intensive to the point of economic absurdity.

The first 50% of recovery is commercially viable.

The next 30% is operationally challenging.

The last 5%?

It becomes a battle against molecular dispersion.

And here’s where I would lean in and say:

“The problem isn’t lack of innovation. The problem is believing innovation overrides physics.”

You can improve efficiency.

You cannot eliminate thermodynamic cost.

The closer you move toward 100%, the more capital, energy, and infrastructure you must deploy for smaller and smaller gains.

At some point, recovery becomes value-destructive.

And if you are a waste operator ignoring that curve, you are building a model that bleeds margin under the illusion of moral superiority.

The smart operator asks:

“Where is optimal recovery?”

Not:

“How do we chase zero?”

Because zero sits behind a thermodynamic barrier.

If you want to understand how to position your waste business around Maximum Exergy Retention instead of fantasy endpoints…

Read The Waste Alchemy.

I explain how to align recovery strategy with economic equilibrium instead of ideological targets.

Get your copy now: https://bit.ly/4sQt4LQ

Don’t build your model on optimism.

Build it on energy balance.

2. “If We Design Products Perfectly for Circularity, Waste Disappears.”

This argument shifts the battlefield.

“Fine,” they say.

“Even if recovery is difficult, we’ll solve it at the design stage.”

Design for disassembly.

Modular components.

Mono-material products.

Material passports.

Again, I support better design.

But here’s the part nobody wants to discuss.

Materials degrade.

Not symbolically.

Physically.

Every industrial transformation introduces irreversibility.

When you:

• Melt metal

• Extrude polymer

• Alloy steel

• Bond composite layers

• Apply surface treatments

• Inject additives

• Polymerize resins

You create entropy.

And entropy does not politely reset itself.

Let’s talk metals.

Each melting cycle accumulates impurities.

Trace elements enter the melt.

Alloy compositions shift.

Oxidation layers form.

You can refine.

But refining consumes energy.

Each cycle requires additional separation.

You cannot infinitely re-melt without quality drift unless you inject additional primary material or energy-intensive purification.

Now plastics.

Polymer chains break under heat.

Mechanical recycling shortens molecular weight.

Mechanical strength drops.

Color consistency degrades.

Additives contaminate future cycles.

After several loops, the polymer is downcycled — not perfectly circular.

Now composites.

Carbon fiber reinforced polymers?

Multi-layer packaging?

Electronics with bonded microstructures?

These are engineered for performance, not reversibility.

Perfect circularity would require:

• Zero contamination

• Zero chemical degradation

• Zero diffusion

• Zero irreversible reactions

Which implies reversible industrial chemistry.

But industrial chemistry is built on irreversibility.

That’s why products function.

That’s why bonds hold.

That’s why structures endure.

Circular design reduces friction.

It does not eliminate entropy.

In The Asymptotic Limit of Circularity, the key insight is simple:

Closed-loop perfection contradicts the Second Law.

Even with perfect labeling, perfect logistics, and perfect consumer behavior, material quality decays unless compensated by additional energy and purification.

Which brings us back to the same question:

At what cost?

And more importantly:

Who pays?

If you are running a waste company, the real strategic advantage is not promising infinite loops.

It’s understanding material degradation curves and positioning yourself at the point of highest recoverable value.

That’s alchemy.

That’s value control.

That’s strategy.

And it’s exactly what I outline inside The Waste Alchemy — how to move from “collection operator” to “material strategist.”

Click here and secure your copy now: https://bit.ly/4sQt4LQ

Stop thinking in circles.

Start thinking in value concentration.

3. “Zero Waste Is Necessary to Save the Planet.”

This is the emotional crescendo.

This is where rational analysis often stops.

“If we don’t aim for zero, we’re irresponsible.”

But physics does not bend to moral urgency.

It responds to energy input.

Chasing literal zero requires:

• Advanced sorting infrastructure

• High-purity separation lines

• Extensive logistics networks

• Sophisticated chemical processing

• Additional transportation cycles

• Redundant recovery facilities

All of which require…

Energy.

Capital.

Mining.

Metals.

Infrastructure.

There is a paradox here that almost nobody articulates:

At extreme recovery targets, the marginal energy cost of extracting the last fraction of material may exceed the environmental burden of primary extraction.

That’s uncomfortable.

But it’s thermodynamically possible.

Because energy is never free.

Even renewable systems require:

Mining.

Processing.

Manufacturing.

Maintenance.

Decommissioning.

The Asymptotic Limit of Circularity explains that entropy production is unavoidable in every transformation.

Which means:

Every recovery step generates new dispersion elsewhere.

The question is not:

“Can we eliminate waste?”

The real question is:

“What level of recovery maximizes net system benefit?”

That’s not a slogan.

That’s systems engineering.

Markets already understand this instinctively.

Scrap prices fluctuate based on:

Purity.

Concentration.

Energy cost.

Processing complexity.

The market prices entropy.

No smelter pays premium prices for highly contaminated micro-dispersed scrap.

No polymer buyer pays premium prices for degraded regrind without specifications.

Zero Waste as an absolute moral endpoint ignores economic gradients.

And economic gradients determine survival.

If you build a waste company chasing ideological perfection, your margins will collapse under energy intensity.

If you build it around optimal recovery, value concentration, and strategic secondary raw materials positioning…

You create leverage.

You become indispensable.

You shift from compliance cost center to resource controller.

This is the structural shift I call the Alchemy Transition.

And it is laid out, step by step, inside The Waste Alchemy.

If you want to operate at a level where physics meets profit…

Get the book here: https://bit.ly/4sQt4LQ

Because saving the planet without understanding thermodynamics is like investing without understanding compound interest.

It sounds noble.

Until reality compounds against you.

The Strategic Conclusion

Let’s summarize without drama.

100% recycling collides with asymptotic energy requirements.

Perfect design cannot eliminate material degradation.

Absolute zero ignores energy balance and marginal cost realities.

Zero Waste is an aspiration.

But aspiration without thermodynamic literacy is dangerous for operators.

The winning position is not anti-recovery.

It is pro-optimal recovery.

It is pro-Maximum Exergy Retention.

It is pro-Strategic Natural Resource Management.

If you are:

• A waste company owner

• A recycler

• An investor

• A secondary raw materials trader

• A policymaker

• A strategist

You cannot afford to ignore entropy.

And you cannot build margins on slogans.

In The Waste Alchemy, I translate thermodynamics into business positioning.

Not theory.

Not activism.

Strategy.

Control.

Leverage.

If this article challenged you — even slightly — then you owe it to yourself to go deeper.

Get your copy of The Waste Alchemy now: https://bit.ly/4sQt4LQ

Because the companies that understand entropy will control the next generation of resource markets.

And the ones chasing zero…

Will chase it forever.

Choose wisely.

To Your Success

Sam

The Waste Management Alchemist

© 2026 Marketing4waste - All Rights Reserved,

Marketing4Waste is a brand of MiM MarketingInterimManagers LLC

+1 801 804 5730